Trenchless sewer line repair-How does it work?

Trenchless sewer line repair-How does it work?

What is trenchless pipe lining repair?

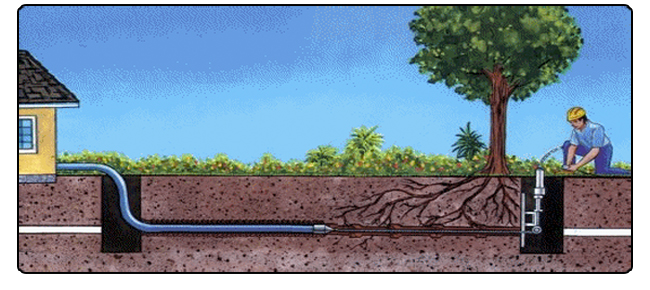

trenchless co pipe lining repair method is used for repairing sewer line without any trench or digging in the ground to expose defective or damaged pipes. During the process, damaged pipe acts like a hose and is repaired internally beneath the ground.A major leading edge of trenchless methods over other is that it follows up repairs once the plumbing is completed and you can cut-off the labor charge that was required for digging before.

Benefits of trenchless pipe lining repair

Trenchless repairing method is eco-friendly as it doesn't involves digging in the ground and the toxic waste isn't directly spilled all around the floor, rather it is kept in a separate disposal. Before 20th century, it was mandatory for the people to move out of their home while the pipe repairing work is on even for several days but trenchless pipe lining repair hardly takes only one day and the homies don't even need to go anywhere till the repairing is done.

The most infuriating problem with conventional repairing methods was that you'd not be able to use washroom or toilet till the repairing is over. But if you're having your repair from a reputed and renowned company then there always be a toilet available for use. Moreover, trenchless pipe bursting denver co offers the same service without excavation, long repair time, toxic wastes, long water supply cut-offs, and trenchless pipe lining repairing is the best choice for modern homeowners across the globe.

How trenchless repairing works?

You can reach out to any reputed denver sewer pipe cleaning company for your sewer line repair, they're most likely to perform the job in four steps:

Pipe inspection

The first and foremost step is to perform a sewer line video inspection to point out the damaged, defective, crushed, and broken pipeline. This process is done from the access point of the sewer line.

Cleaning

The interiors of the pipe are cleaned to ensure that liner aligns correctly. By chance if tree roots are found inside the pipe then a rotatory blade cuts the roots and clears the passage. Blade cutting is the most commonly used method for removing tree roots.

Pipe lining

An inflated tube covered with epoxy is inserted into the sewer line. Then at the broken point, inflated tube is pressed against the interior wall of the pipe so that the epoxy settles on the cracked portion. After sometime the line gets hardened and ready for use.

Final inspection

A final inspection is made after all the work is done to ensure proper functionality of the pipe. Now, the pipe will endure another 50 years.

| Карта сайта:

| Карта сайта: